Leather dyeing can be challenging and requires patience and skill to achieve the desired outcome. Despite taking the necessary precautions and following the instructions, sometimes things can go wrong during the dyeing process. Common issues that can occur include uneven colour, fading, spotting, and streaking. To help you overcome these challenges, this article will provide an overview of some of the most common leather dyeing problems and how to fix them. Whether you are a professional leather worker or a DIY enthusiast, these tips will significantly assist in achieving a flawless and long-lasting dye job.

Importance Of Understanding Common Problems In Leather Dyeing

Understanding common problems in leather dyeing are crucial as it can help prevent mistakes and ensure a successful outcome. By being aware of the potential issues, such as uneven colour, staining, fading, and crackling, leather workers can take the necessary steps to avoid these problems. Knowing how to fix these issues can save time and money and prevent the waste of materials. In short, understanding the common issues in leather dyeing is an essential aspect of the leatherworking process and can help ensure a high-quality end product.

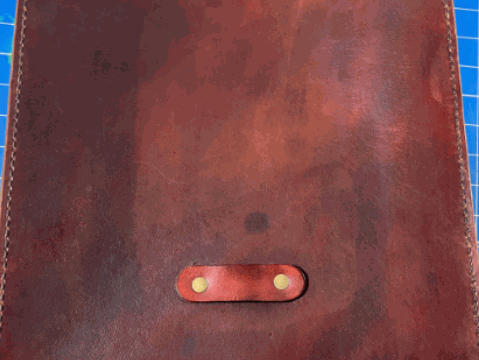

Uneven Colour

Uneven colour is a common problem in leather dyeing that can result from several causes, such as improper preparation, improper application of dye, or a mismatch between the leather and dye type. To fix uneven colour, it is crucial to prepare the leather properly, apply the stain evenly, and finish it using proper techniques. Other solutions include choosing the right type of dye and selecting a suitable finish to protect the leather. With proper preparation and application, a leather worker can achieve a uniform colour on their leather projects.

How To Fix Uneven Colour

Uneven colour in leather dyeing is a common problem that various factors, including improper preparation of the leather, improper application of dye, or improper finishing of the leather, can cause. To fix uneven colour, it is crucial to understand the cause of the problem and take steps to correct it. This may include preparing the leather properly, applying the dye evenly and in the right amount, and using the proper finishing techniques to ensure even colour distribution. It may be helpful to use a high-quality paint specifically designed for leather and protect the leather from exposure to sunlight, heat, and other factors that can cause fading or discoloration.

How To Fix Fading

Fading is a common problem in leather dyeing, causing the colour to become dull and fade over time. The cause of fading can be sunlight, heat, and moisture exposure. It is crucial to choose the correct type of dye to fix sagging and apply it correctly. A high-quality leather dye will resist fading and last longer. When using the paint, it is critical to follow the manufacturer's instructions and ensure that the leather is prepared correctly. Protecting the leather from fading is crucial by avoiding exposure to direct sunlight, heat, and moisture. This can be done by using a leather protectant or storing the leather in a cool, dry place. Taking proper precautions and choosing the right type of dye is critical to fixing fading in leather.

How To Fix Bleeding

Leaving an unwanted residue. To fix this issue, the first step is to choose the right type of dye. Leather dye specifically formulated for the leather dyed is recommended to minimise the risk of bleeding. The leather must be properly prepared before applying the stain. This includes cleaning the leather thoroughly and ensuring it is free from any oils or substances that could interfere with the dye’s adhesion. Sealing the leather after dyeing is crucial to prevent further bleeding. This can be done by applying a topcoat or sealant to the leather, which helps to lock in the colour and protect it from damage.

Finishing The Leather

Finishing the leather is a crucial step in the leather dyeing process. It not only enhances the appearance of the leather but also protects it from external damage. The type of finish applied to the leather depends on the desired end result. For example, a matte finish will produce a soft, natural look, while a gloss finish will give the leather a shiny, high-gloss appearance. To achieve a consistent finish, it is crucial to apply the finish evenly and allow enough time to dry. This will help to avoid streaks and ensure a uniform look. Some standard finishing methods include spray finishes, brush finishes, and roller finishes. The choice of method will depend on the type of finish desired and the desired outcome.

How To Fix Colour Changes

Leather colour changes can occur due to various factors such as exposure to sunlight, chemicals, or heat. To fix colour changes, one must first understand the cause of the change. Choosing the correct type of dye is crucial, as some stains may cause colour changes over time. Proper preparation of the leather is also essential, as dirt, oil, and other impurities can affect the final colour. The leather must be cleaned and treated before applying the dye. Lastly, sealing the leather after dying can help prevent colour changes from occurring in the future. It is important to note that fixing colour changes in the leather may require multiple steps and applications of dye to achieve the desired result.

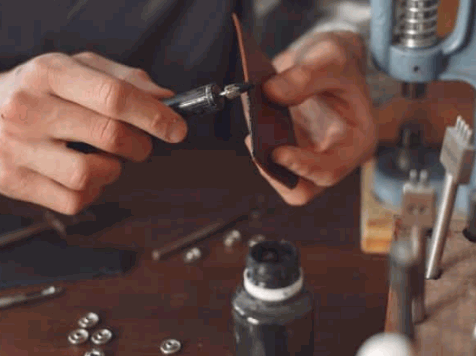

Proper Preparation Of The Leather

Proper preparation of the leather is essential for achieving the desired outcome in leather dyeing. The leather should be cleaned, degreased, and sanded to remove any impurities and create a smooth surface for the dye to adhere to. The leather should also be conditioned to improve its dye absorption and maintain its natural properties. Any cracks or holes should also be repaired before dyeing to prevent the dye from seeping into the leather and causing discoloration. Proper preparation of the leather will ensure the even application of the stain and increase the longevity of the colour.

Check out: Couch Cleaning Tips

Sealing The Leather

Sealing the leather after dyeing is crucial in preserving the colour and preventing any unwanted changes over time. Locking the leather protects it from the elements and helps to prevent fading, bleeding, and streaking. Various types of leather sealants are available, including water-based and oil-based options. Every kind of sealant provides a different level of protection, so choosing the right one for your specific leather type and desired outcome is crucial. Once the leather has been properly sealed, it should be allowed to dry completely before being used or handled. By closing the leather, you can ensure that the colour remains vibrant and protected for years.

Leather dyeing is a delicate process that requires attention to detail and the right tools. The common problems encountered while dyeing leather can be frustrating, but they can be resolved with patience and the right solutions. If you need any help with your leather dyeing process, we are here to help. Call us today or visit our website for more information and assistance with your leather dyeing needs. With our expertise and experience, you can ensure that your leather dyeing project is a success.

Before you go, take a look at our other articles that explain what does bouclé mean and what is taffeta.