In the world of concrete floors, resin is a commonly used material for its durability, versatility, and aesthetic appeal. There may come a time when you need to remove resin from a concrete floor, whether it's due to wear and tear, a change in design, or the need for maintenance. In this comprehensive guide, we will delve into the various types of resin used on concrete floors, the tools needed for removal, safety precautions, and step-by-step methods for removing resin.

We will explore alternative solutions and provide valuable tips for cleaning and maintaining concrete floors post-resin removal. Whether you're a homeowner, business owner, or contractor, this article aims to equip you with the knowledge and practical insights needed to effectively navigate the process of resin removal from concrete floors. So, let's dive into the intricacies of this essential task and empower you to achieve successful results.

What Is Resin?

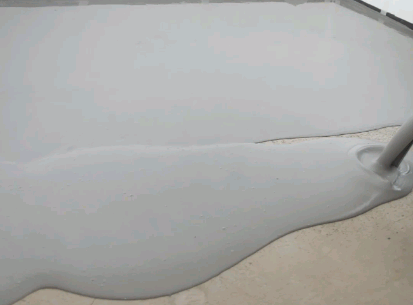

Resin is a viscous substance derived from organic sources or synthesized through chemical processes, commonly used to provide a protective layer or finish on various surfaces, including concrete floors.

It is composed of polymers, which allow it to form a durable and resilient coating. The versatility of resin makes it suitable for applications ranging from industrial warehouses to residential garage floors. Its ability to resist abrasion, chemicals, and moisture makes it particularly valuable for protecting concrete surfaces.

Resin can be customized to offer various levels of sheen, from matte to high-gloss, enhancing the aesthetic appeal of concrete floors while simultaneously providing excellent surface protection.

Why Is Resin Used On Concrete Floors?

Resin is applied to concrete floors to enhance durability, protect against stains and damage, and facilitate maintenance, making it a popular choice for surface treatment and long-term preservation.

It creates a seamless, non-porous surface that resists moisture, making it ideal for areas prone to spills and water exposure. Resin-coated floors are easier to clean and maintain, requiring less maintenance and reducing long-term costs. The application of resin also provides an attractive finish, offering a sleek and polished appearance to the concrete floors, enhancing the overall aesthetic and value of the space.

Resin coatings can help to level uneven surfaces and fill in cracks, enhancing the structural integrity of the concrete floors and preventing further damage over time.

Delve into: How To Apply Epoxy Resin Floor Paint

What Are The Types Of Resin Used On Concrete Floors?

Various types of resin are utilized on concrete floors, including sealants, adhesives, and epoxy coatings, each offering distinct properties and applications tailored to specific surface requirements.

These resins play a crucial role in enhancing the durability, chemical resistance, and aesthetic appeal of concrete surfaces. Epoxy coatings, for instance, are renowned for their superior bond strength and seamless finish, making them ideal for high-traffic areas. On the other hand, polyurethane sealants are valued for their flexibility and resistance to abrasion, making them suitable for outdoor applications.

Understanding the unique characteristics and applications of each resin type is essential for achieving long-lasting protection and maintaining the visual appeal of concrete floors.

What Are The Tools Needed To Remove Resin From Concrete Floors?

Removing resin from concrete floors requires specific tools such as a heat gun, scrapers, and solvent-based cleaners to effectively dissolve and eliminate the resinous residue from the surface.

The heat gun is essential for softening the resin, making it easier to scrape off with the scrapers. In addition, a sturdy scraper with a sharp edge is crucial for physically removing the softened resin from the concrete without causing damage.

Solvent-based cleaners are then used to further dissolve and lift any remaining residue, ensuring a thorough clean. Proper safety gear, such as gloves and goggles, should also be worn during the process to prevent direct contact with the resin and cleaning agents.

How To Prepare The Concrete Floor For Resin Removal?

Before initiating the resin removal process, it is crucial to thoroughly clean the concrete floor, consider the use of solvents if needed, and ensure proper surface preparation to facilitate effective resin elimination.

This involves first removing any surface debris and dust, followed by scrubbing the floor to remove any lingering dirt or contaminants. Then, apply a suitable solvent to dissolve any stubborn residues on the surface, making sure to follow safety guidelines for handling and ventilating the area.

Once the concrete is clean and solvent-free, the surface should be left to dry completely to ensure optimal readiness for the resin removal process.

What Are The Safety Precautions To Take Before Removing Resin?

Prior to resin removal, it is essential to implement safety precautions such as:

- wearing protective gear

- ensuring adequate ventilation

- preventing direct skin contact with the resin or associated cleaning solvents

Protective gear, including gloves, goggles, and a respirator, should be worn to shield the skin, eyes, and respiratory system from potential exposure to hazardous fumes and substances during the resin removal process. Adequate ventilation is critical to dissipate fumes and prevent the buildup of airborne particles, requiring the use of exhaust fans or open windows. Minimizing direct skin contact by using tools and equipment for handling and transferring the resin can help reduce the risk of skin irritation or sensitization. These measures are crucial for safeguarding both personal health and the surrounding environment.

How To Remove Resin From Concrete Floors?

There are several techniques for removing resin from concrete floors, including the use of chemical strippers, pressure washing, and solvent-based cleaners, each offering specific advantages for the resin elimination process.

Chemical strippers are effective for breaking down and dissolving the resin, making it easier to scrape or wash away. Pressure washing employs high-pressure water to dislodge and remove the resin from the concrete surface, especially useful for larger areas or stubborn residues. Solvent-based cleaners can penetrate the resin to weaken its adhesion, allowing for easier extraction.

Each method requires careful consideration of the type of resin, surface preparation, and environmental considerations to ensure effective and safe resin removal.

Use A Chemical Stripper

Utilizing a chemical stripper is an effective method for removing resin from concrete floors, as it facilitates the dissolution of the resin and assists in preparing the surface for subsequent treatments or finishes.

This process involves applying the chemical stripper to the affected area and allowing it to penetrate the resinous residues, breaking down their adhesive properties. Once the stripper has had time to work, the resin can be easily removed, leaving the concrete surface ready for further treatment.

Chemical strippers are particularly useful for large surface areas and offer a cost-effective and efficient solution for resin removal, making them a popular choice in various industries requiring thorough surface preparation and material cleaning.

Use A Floor Grinder

Employing a floor grinder is a viable option for resin removal from concrete floors, offering efficient material removal and surface preparation capabilities, particularly for larger or more stubborn resin deposits.

These machines are essential for the maintenance and upkeep of concrete floors, as they effectively eliminate tough resin build-up that may compromise the floor's integrity. Their high-speed grinding action ensures thorough removal of resin, leaving behind a clean and pristine surface. Floor grinders play a crucial role in material preparation for subsequent treatments, such as coatings or sealants, by ensuring a properly leveled and smooth surface. Their versatility and adaptability make them indispensable for addressing substantial resin accumulations and maintaining the quality of concrete floors over time.

Use A Heat Gun

Employing a heat gun is an effective technique for softening and loosening resin deposits on concrete floors, enabling easier removal through scraping or mechanical means, particularly for localized or adhesive resin residues.

This method is particularly useful for targeted applications, as the heat gun allows for precise control over temperature and application area. By gradually applying heat to the resin-affected areas, the resin softens, making it easier to scrape or peel off. The heat gun's portability and versatility make it suitable for various sizes and types of resin deposits, making the process more efficient and cost-effective for resin removal on concrete surfaces.

What Are The Alternatives To Removing Resin From Concrete Floors?

In addition to direct resin removal, alternative approaches include covering the resin with a new layer, or sanding down the resin, providing DIY options for addressing minor resin-related issues on concrete floors.

Each method has its pros and cons. When covering the resin with a new layer, you have the opportunity to create a fresh, seamless surface. Proper surface preparation is crucial to ensure the new layer adheres well. On the other hand, sanding down the resin may require more time and effort, but it can effectively restore the concrete's natural appearance.

For preventive measures, applying a high-quality sealant can protect the concrete and make it easier to clean.

Covering The Resin With A New Layer Of Resin

A viable alternative to removing resin from concrete floors involves applying a new layer of resin to cover existing resinous deposits, offering a seamless solution with adhesive or epoxy-based applications.

This process not only saves time and effort but also provides a durable and visually appealing surface. Adhesives or epoxy coatings used in this method ensure proper bonding, creating a strong, protective layer over the existing resin.

Surface preparation is crucial for adhesion, involving thorough cleaning and roughening of the existing resin layer to ensure proper material coverage. The application of new resin layers not only revitalizes the appearance of the concrete floor but also enhances its longevity by providing added protection against wear and tear.

Sanding The Resin Down

Sanding down resin deposits on concrete floors is a practical alternative to removal, allowing for the smoothing and repair of minor resin imperfections or irregularities without necessitating complete material elimination.

This process involves using specialized sanding equipment to gradually remove the top surface of the resin, effectively eliminating blemishes and creating a more uniform appearance. By scraping away the excess resin, the concrete floor's underlying structure can be revealed, and any uneven areas can be leveled out. This method saves time and resources compared to the extensive labor and cost involved in complete removal and replacement, making it a cost-effective and efficient solution for resin repair and surface refinement.

How To Clean And Maintain Concrete Floors After Resin Removal?

Post-resin removal, cleaning, and maintenance of concrete floors involve regular sweeping, mopping, and the application of sealants or absorbent materials to uphold surface integrity and prolong the effects of the resin treatment.

This comprehensive cleaning process not only removes any remaining residue from the resin removal but also helps eliminate dust, dirt, and grime that can accumulate on the floor surface.

Sweeping ensures that loose particles are cleared away while mopping effectively removes any lingering residue.

The application of sealants or absorbent materials serves as a protective barrier, preventing stains, moisture penetration, and wear, thereby extending the lifespan of the concrete flooring.

Sweep And Mop Regularly

Regular sweeping and mopping are essential maintenance routines for concrete floors after resin removal, ensuring proper cleanliness and surface preparation to maintain the effects of the treatment over time.

These routine cleaning activities play a crucial role in preventing the accumulation of debris, dust, and other particles. By regularly clearing the surface, the longevity of the resin removal treatment can be preserved, ensuring that the concrete floors retain their enhanced appearance and durability.

Consistent sweeping and mopping aid in preventing the re-adherence of contaminants, and preparing the surface for any subsequent maintenance or refinishing processes. This ongoing care helps in upholding the cleanliness and integrity of the concrete floors, promoting a hygienic and visually appealing environment.

Use A Neutral Cleaner

Utilizing a neutral cleaner is recommended for the ongoing maintenance of concrete floors after resin removal, ensuring effective cleaning without compromising surface preparation or the effects of prior treatments.

These cleaners are formulated to maintain the pH balance of the concrete, preventing any damage while effectively removing dirt, grime, and residue. Their gentle yet powerful nature makes them ideal for regular use, helping to keep the concrete surface in prime condition.

Neutral cleaners play a crucial role in preparing the surface for any future treatments or coatings, ensuring that the floor is ready for the next steps in maintenance and upkeep. By incorporating these cleaners into a routine cleaning regimen, the longevity and appearance of concrete floors can be significantly enhanced.

Apply A Sealant

Applying a sealant after resin removal enhances the durability and protective properties of concrete floors, acting as a preventive measure against potential damage and ensuring long-term surface integrity.

Sealants act as a barrier, preventing liquids, oils, and other substances from seeping into the concrete, which can cause discoloration and deterioration over time. By sealing the surface, it becomes easier to maintain and clean, as dirt and stains are less likely to penetrate deeply. Sealants can also enhance the aesthetic appeal of the concrete, providing a glossy or matte finish depending on the preferences of the owner. This helps to maintain a professional and well-maintained appearance for commercial and residential spaces alike.