Epoxy resin floor paint has become a popular choice for both residential and commercial spaces due to its numerous benefits and versatile applications. From its exceptional durability and chemical resistance to its aesthetic appeal and easy maintenance, epoxy resin floor paint offers a wide range of advantages for various surfaces.

In this comprehensive guide, we will explore what epoxy resin floor paint is, its benefits, the different types available, surface preparation, application techniques, and essential tips for a successful application. Whether you are a DIY enthusiast or a professional contractor, this article will provide you with the essential knowledge and practical tips to make your epoxy resin floor paint application a success. So let's dive into the world of epoxy resin floor paint and discover how you can transform your floors with this versatile and durable coating.

What Is Epoxy Resin Floor Paint?

Epoxy resin floor paint is a type of coating that is applied to surfaces to provide a seamless and durable finish. It is known for its exceptional strength, resistance to chemicals, and ability to withstand heavy foot traffic, making it a popular choice for industrial and commercial settings. The application process involves careful surface preparation, including cleaning, etching, and patching any cracks or imperfections to ensure optimal adhesion. Once the preparation is complete, the epoxy resin is applied using various techniques such as roller or squeegee, followed by a protective topcoat for added durability.

The benefits of epoxy resin floor paint include its resistance to stains, easy maintenance, and long-lasting performance, making it an excellent investment for high-traffic areas.

Uncover more: How To Make Epoxy Floor Design

What Are The Benefits Of Using Epoxy Resin Floor Paint?

The application of epoxy resin floor paint offers several benefits, including exceptional durability, chemical resistance, and an aesthetically pleasing finish.

Durability

One of the key benefits of epoxy resin floor paint is its exceptional durability, which provides a seamless and protective coating for surfaces.

This robust coating offers long-lasting protection against heavy foot traffic, vehicle movement, and various chemical spills. Epoxy resin floor paint forms a solid, impermeable barrier that minimizes wear and tear on the underlying surface, making it an ideal choice for high-traffic areas such as industrial spaces, garages, and commercial facilities.

Its ability to withstand abrasion and impact also contributes to its durability, ensuring that the flooring maintains its pristine appearance for an extended period. Its resistance to UV rays and harsh environmental conditions makes it a reliable option for both indoor and outdoor applications.

Chemical Resistance

Epoxy resin floor paint exhibits remarkable chemical resistance, making it ideal for waterproofing and protecting various surfaces.

With its ability to withstand corrosive substances and harsh chemicals, epoxy resin floor paint provides a protective barrier against moisture and chemical spills. This makes it a popular choice for industrial and commercial environments, where durability and resistance to wear and tear are crucial. Its seamless application creates a waterproof surface, preventing water damage and ensuring long-term structural integrity.

The epoxy resin floor paint not only enhances the aesthetic appeal of floors but also serves as a reliable shield, guarding against chemical damage and maintaining a pristine appearance.

Easy Maintenance

The application of epoxy resin floor paint facilitates easy maintenance, ensuring longevity and simplifying cleaning processes for the coated surfaces.

This type of floor coating creates a seamless, smooth surface that resists dirt, dust, and spills, allowing for effortless cleaning with just soap and water. The durable nature of epoxy resin withstands heavy foot traffic and abrasion, reducing the need for regular touch-ups or replacements.

The low maintenance requirements of epoxy resin floor paint make it an ideal choice for high-traffic areas in residential, commercial, and industrial settings.

Aesthetics

Epoxy resin floor paint enhances the aesthetics of surfaces, offering a smooth and visually appealing finish that elevates the overall appearance.

The coating creates a seamless and glossy surface that reflects light, giving the coated area a modern and sophisticated look. It not only masks any imperfections in the original surface but also provides a durable and resilient layer that can withstand heavy foot traffic and various environmental pressures.

The visual appeal of epoxy resin floor paint makes it a popular choice for commercial and residential spaces, transforming dull and worn-out floors into attractive and vibrant areas.

What Are The Different Types Of Epoxy Resin Floor Paint?

Epoxy resin floor paint is available in various types, including:

- Solvent-based

- Water-based

- 100% solids formulations

Each is tailored to specific application requirements.

Solvent-based epoxy resin floor paint offers excellent adhesion to concrete and is ideal for industrial settings due to its resistance to chemicals and abrasion.

On the other hand, water-based epoxy paint is suitable for residential and commercial spaces, offering low odor and easy cleanup.

Meanwhile, 100% solids formulations provide a durable, high-performance coating with no volatile organic compounds (VOCs), making them environmentally friendly and suitable for food and beverage facilities.

Solvent-Based Epoxy Resin Floor Paint

Solvent-based epoxy resin floor paint is a type of coating that offers specific application advantages for various surfaces, catering to specific project requirements.

It provides exceptional durability, chemical resistance, and a high-gloss finish, making it ideal for industrial floors, garages, warehouses, and commercial facilities. Its seamless application ensures a smooth, easily cleanable surface, enhancing safety and hygiene. Its versatility extends to concrete, metal, and wood surfaces, allowing for broad project applications.

The option for customizable colors and textures further enhances its suitability for decorative or branding purposes in retail or hospitality settings.

Water-Based Epoxy Resin Floor Paint

Water-based epoxy resin floor paint provides a versatile and environmentally friendly application option for a wide range of surfaces, ensuring optimal performance and aesthetic appeal.

This type of epoxy is known for its low VOC content, making it a sustainable choice for indoor and outdoor use. Its seamless application creates a durable, high-gloss finish that resists chemicals, abrasion, and heavy foot traffic, making it ideal for commercial, industrial, and residential spaces.

Water-based epoxy resin floor paint is easy to clean and maintain, offering long-term cost savings. Its ability to adhere to various substrates, including concrete and wood, further enhances its practicality for diverse applications.

100% Solids Epoxy Resin Floor Paint

100% solids epoxy resin floor paint is renowned for its seamless coverage and exceptional durability, making it an ideal choice for high-traffic and demanding environments.

Its high-performance formulation ensures a smooth and impermeable surface, resistant to chemical spills, heavy impacts, and abrasion. This makes it perfect for industrial facilities, warehouses, garages, and commercial kitchens.

Its seamless finish prevents the growth of bacteria and mold, enhancing hygiene and making it suitable for healthcare facilities and pharmaceutical plants. The versatility of 100% solids epoxy resin floor paint extends to decorative applications, providing a durable and appealing flooring solution for retail spaces and showrooms.

Its ability to withstand extreme temperatures and harsh conditions makes it a reliable choice for both interior and exterior use, offering long-lasting protection and aesthetic appeal.

How To Prepare The Surface For Epoxy Resin Floor Paint?

Effective surface preparation is crucial for the successful application of epoxy resin floor paint, involving cleaning, repairing, and applying a suitable primer to ensure optimal adhesion and performance.

Cleaning the surfaces thoroughly is the initial step, removing any dirt, grease, or old paint to achieve a clean and smooth base. Repairing any cracks, holes, or imperfections in the surface is essential to ensure a uniform and durable finish.

After cleaning and repairing, the application process begins with the suitable primer, which creates a strong bond between the surface and the epoxy resin floor paint, allowing for a long-lasting and professional-looking result.

Cleaning The Surface

Thoroughly cleaning the surface is the first step in preparing for the application of epoxy resin floor paint, ensuring the removal of contaminants and achieving an optimal bonding surface.

This process is crucial as it eliminates any dirt, grease, or oil that may have accumulated on the surface, which could undermine the adhesion of the epoxy resin. It creates a suitable environment for the epoxy to bond effectively with the substrate, promoting the durability and longevity of the paint.

Neglecting this cleaning step can lead to poor adhesion and premature paint failure, emphasizing the significance of thorough surface cleaning for successful epoxy resin floor paint application.

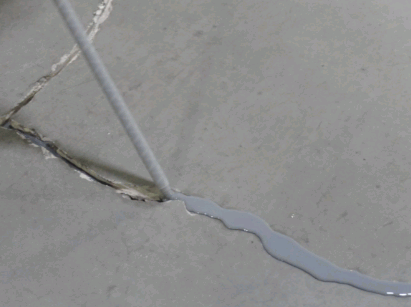

Repairing Any Cracks Or Holes

Addressing any cracks or holes in the surface is essential as part of the preparation process for applying epoxy resin floor paint, ensuring a smooth and uniform substrate.

This is important because a pristine and even surface allows the epoxy resin to adhere properly, preventing air bubbles and ensuring a seamless finish. Surface imperfections can compromise the durability and aesthetics of the coating, potentially leading to premature wear and tear. Proper repair also enhances the overall performance of the epoxy resin floor, providing a strong foundation for long-term use. Therefore, meticulous attention to surface preparation is crucial for achieving a successful and enduring epoxy resin floor paint application.

Sanding The Surface

Sanding the surface facilitates optimal adhesion and promotes the bonding of the epoxy resin floor paint, ensuring a well-prepared substrate for the coating application.

This process of sanding plays a crucial role in achieving a smooth and even surface, which is essential for the successful application of epoxy resin floor paint. By removing imperfections and creating a textured surface, sanding enhances the mechanical grip of the paint, allowing it to adhere firmly to the substrate.

It also helps to clean the surface from any contaminants, ensuring that the epoxy resin can bond effectively with the prepared substrate. Without proper sanding, the adhesion of the epoxy resin floor paint may be compromised, leading to problems such as peeling, flaking, or uneven finish.

Applying A Primer

The application of a suitable primer is a critical step in surface preparation for epoxy resin floor paint, enhancing adhesion and ensuring the coating's performance and longevity.

It acts as a bonding agent, creating a strong bond between the substrate and the epoxy resin, preventing peeling or delamination. The primer helps to seal porous surfaces, preventing outgassing and ensuring a smooth and even application of the epoxy resin floor paint.

By providing a clean and stable surface, the primer enables the epoxy resin to adhere effectively, promoting a durable and long-lasting finish. Proper primer application is essential for achieving a professional and high-quality epoxy resin floor finish.

How To Apply Epoxy Resin Floor Paint?

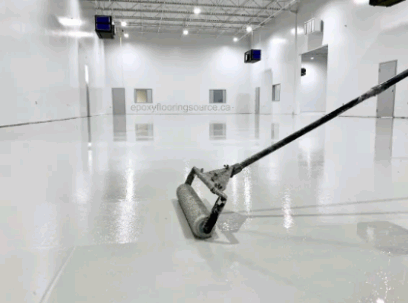

The application of epoxy resin floor paint involves a precise process, including mixing, pouring, leveling, and curing, to ensure a seamless and durable coating.

Once the epoxy resin and hardener are thoroughly mixed according to the manufacturer's instructions, the next step is to pour the mixture onto the prepared floor surface. Careful attention should be paid to spreading the resin evenly to avoid build-up or thin patches.

After pouring, the resin needs to be leveled using a squeegee or roller to achieve a uniform thickness. Once leveled, the curing process begins, where the resin is left undisturbed to allow it to harden and create a strong, protective finish.

Mixing The Epoxy Resin And Hardener

The initial stage of applying epoxy resin floor paint involves meticulous mixing of the resin and hardener to achieve the correct consistency and optimal performance.

This precise mixing is crucial as it ensures that the resin and hardener react effectively, forming a strong bond and durable surface. Properly mixed epoxy resin also enhances the paint's flow and self-leveling properties, resulting in a smooth finish. An accurately mixed epoxy resin floor paint minimizes the risk of delamination, blistering, or uneven curing, improving the overall performance and longevity of the flooring.

Techniques such as double-mixing and using proper tools further contribute to achieving a seamless application and a professional-quality result.

Applying The First Coat

Applying the first coat of epoxy resin floor paint requires attention to detail and uniform coverage to establish a solid foundation for the subsequent layers. This initial application not only acts as a base for additional coats but also ensures that the floor surface is properly sealed and protected. It is crucial to carefully follow the manufacturer's instructions for mixing and application to achieve optimal adhesion and durability.

The first coat sets the stage for the overall performance and longevity of the epoxy resin flooring system, making it essential for delivering the desired level of strength, resistance, and aesthetic appeal.

Applying The Second Coat

The application of the second coat of epoxy resin floor paint builds upon the foundation laid by the initial coat, enhancing the durability and finish of the coating.

This additional layer serves as a protective barrier, further reinforcing the resistance of the floor against abrasion, chemicals, and daily wear and tear. The second coat also plays a crucial role in achieving a smooth and flawless surface, minimizing imperfections, and ensuring a professional-looking finish. By applying the second coat, the epoxy resin forms a stronger bond, prolonging the lifespan of the flooring and maintaining its aesthetic appeal over an extended period. It is a critical step in the epoxy resin floor painting process, significantly impacting the overall performance and longevity of the coating.

Adding A Topcoat (Optional)

The addition of a topcoat is an optional step in the application process of epoxy resin floor paint, providing an extra layer of protection and a polished finish.

Applying a topcoat enhances the durability of the epoxy resin, safeguarding it against abrasions, chemical spills, and UV radiation. It can bring out a glossy sheen, adding aesthetic appeal to the flooring. This extra layer also ensures that the epoxy resin maintains its high-performance characteristics over time, contributing to a longer lifespan for the flooring.

While not mandatory, opting for a topcoat can substantially improve the overall quality and resilience of the epoxy resin floor paint.

What Are The Tips For A Successful Epoxy Resin Floor Paint Application?

Achieving a successful application of epoxy resin floor paint requires adherence to essential tips, including proper ventilation, drying time considerations, and meticulous application techniques.

Proper ventilation is crucial when working with epoxy resin as it helps to dissipate fumes and ensures a safer working environment. Allowing adequate drying time between coats is important for the resin to cure properly and achieve a durable finish.

When it comes to application techniques, ensuring a clean and smooth surface, using the right tools, and following the manufacturer's instructions is key to a successful epoxy resin floor paint application.

Follow The Instructions Carefully

Carefully following the instructions provided for epoxy resin floor paint application is crucial to ensure safety, optimal techniques, and a successful outcome.

This involves meticulously adhering to safety precautions, such as wearing protective gear and ensuring proper ventilation in the workspace. Utilizing the recommended tools and techniques, including priming the surface and applying the epoxy resin in an even manner, is pivotal for achieving a durable and visually appealing finish. The provided guidelines typically offer specific details about surface preparation, mixing ratios, and curing times, all of which play a significant role in the effectiveness of the epoxy resin floor paint. By complying with these instructions, the application process is streamlined and the desired results are more likely to be achieved.

Work In Small Sections

Working in small sections during the application process of epoxy resin floor paint ensures precise coverage, uniform thickness, and meticulous attention to detail.

This technique allows for greater control over the application, resulting in a professional finish with minimal errors. It also enables the careful inspection of each section, ensuring that imperfections are addressed immediately. By breaking the process into small segments, it becomes manageable and less overwhelming, promoting a more relaxed and focused approach. Working in small sections facilitates the incorporation of decorative elements or patterns, enhancing the aesthetic appeal of the epoxy resin floor.

Use Proper Ventilation

Maintaining proper ventilation throughout the epoxy resin floor paint application process is essential to ensure safe working conditions and optimal curing in varied temperature and humidity levels.

This ventilation is crucial for minimizing the risk of inhaling harmful fumes, especially in enclosed or poorly ventilated spaces. Adequate airflow helps in expediting the curing process by allowing solvents to evaporate efficiently, leading to a durable and flawless finish.

Proper ventilation plays a significant role in promoting environmental sustainability by reducing air pollutants and minimizing the impact on indoor air quality. Hence, ensuring proper ventilation is integral for achieving successful epoxy resin floor paint applications.

Allow Sufficient Drying Time

Allowing sufficient drying time is critical for the successful application of epoxy resin floor paint, contributing to a durable finish and long-term maintenance benefits.

This is essential as the drying process directly impacts the adhesion and strength of the epoxy coating, ensuring that it properly bonds with the substrate. Inadequate drying time can lead to premature wear and a lackluster finish that is prone to chipping and peeling. By allowing ample time for drying, the floor paint can achieve its full potential, offering enhanced durability and resistance to heavy foot traffic, chemicals, and abrasions.